Visit Our Website

To learn more about our services.

LIQUID BOOT® — Gas Vapor Barrier System

System Description

Liquid Boot® is a seamless, spray-applied, water-based membrane containing no VOCs, which provides a barrier against vapor intrusion into structures

Liquid Boot® is installed under slab and on below grade vertical walls as a gas vapor barrier to minimize vapor and nuisance water migration into buildings and is ideal for methane migration control.

Liquid Boot® spray-application directly to penetrations, footings, grade beams, pile caps, etc., provides for a fully-adhered gas vapor barrier system.

Typical Uses

Underslab and below-grade vertical wall gas vapor barrier, used to minimize vapor and

nuisance water (non-hydrostatic conditions) migration into buildings.

Ideal for methane migration control.

Concrete water reservoir and tank liner used to prevent water seepage into concrete.

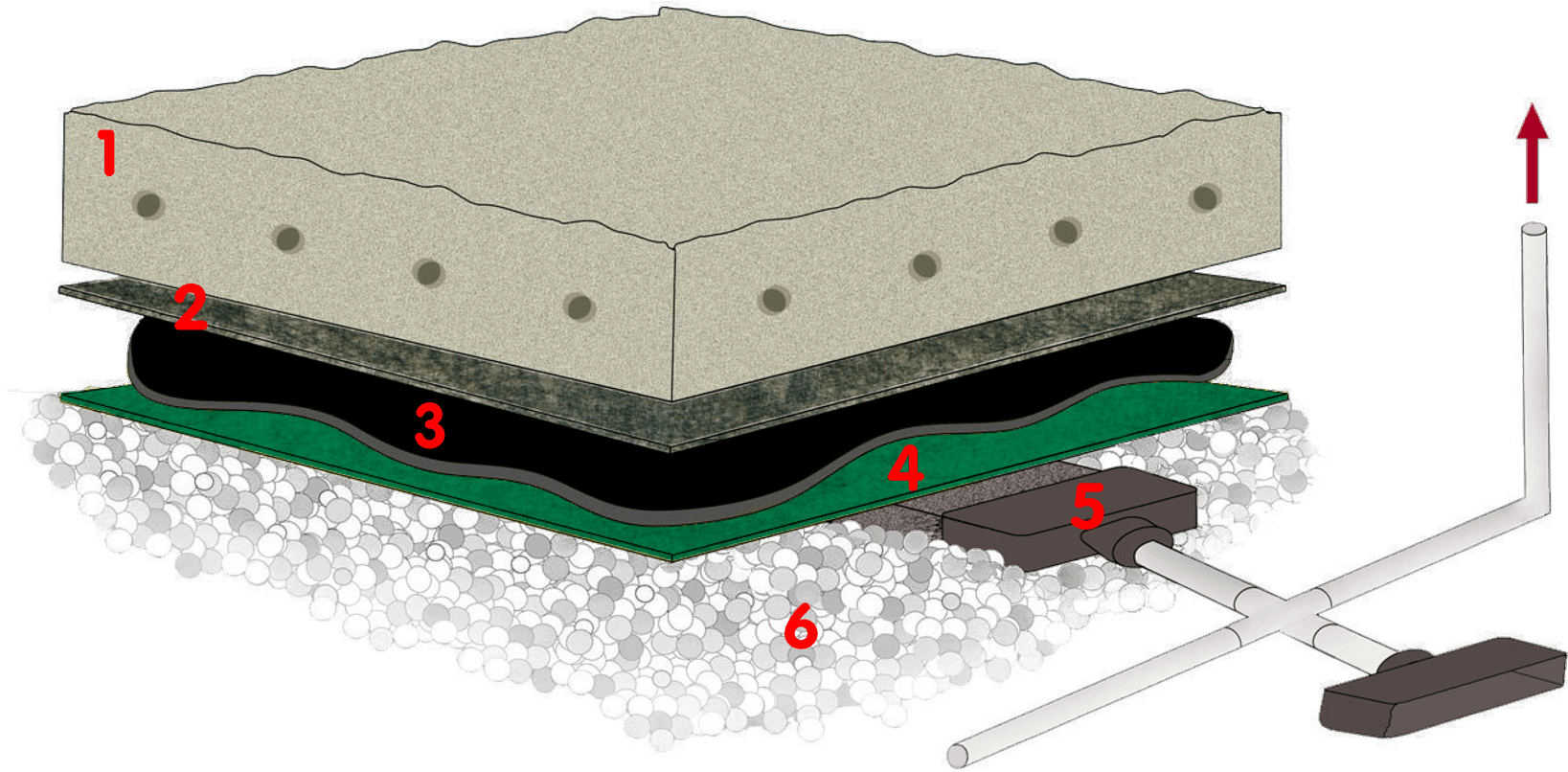

Structural Slab

UltraShield™ Protection Layer

LIQUID BOOT®

BaseFabric™ Base Layer

GeoVent™ System

Subgrade

Benefits

Spray application provides excellent sealing of penetrations, eliminating mechanical fastening.

Seamless, monolithic membrane eliminates seaming-related membrane failures.

Unique formulation provides superior protection from methane gases and water vapor.

Fully adhered system reduces risk of gas migration.

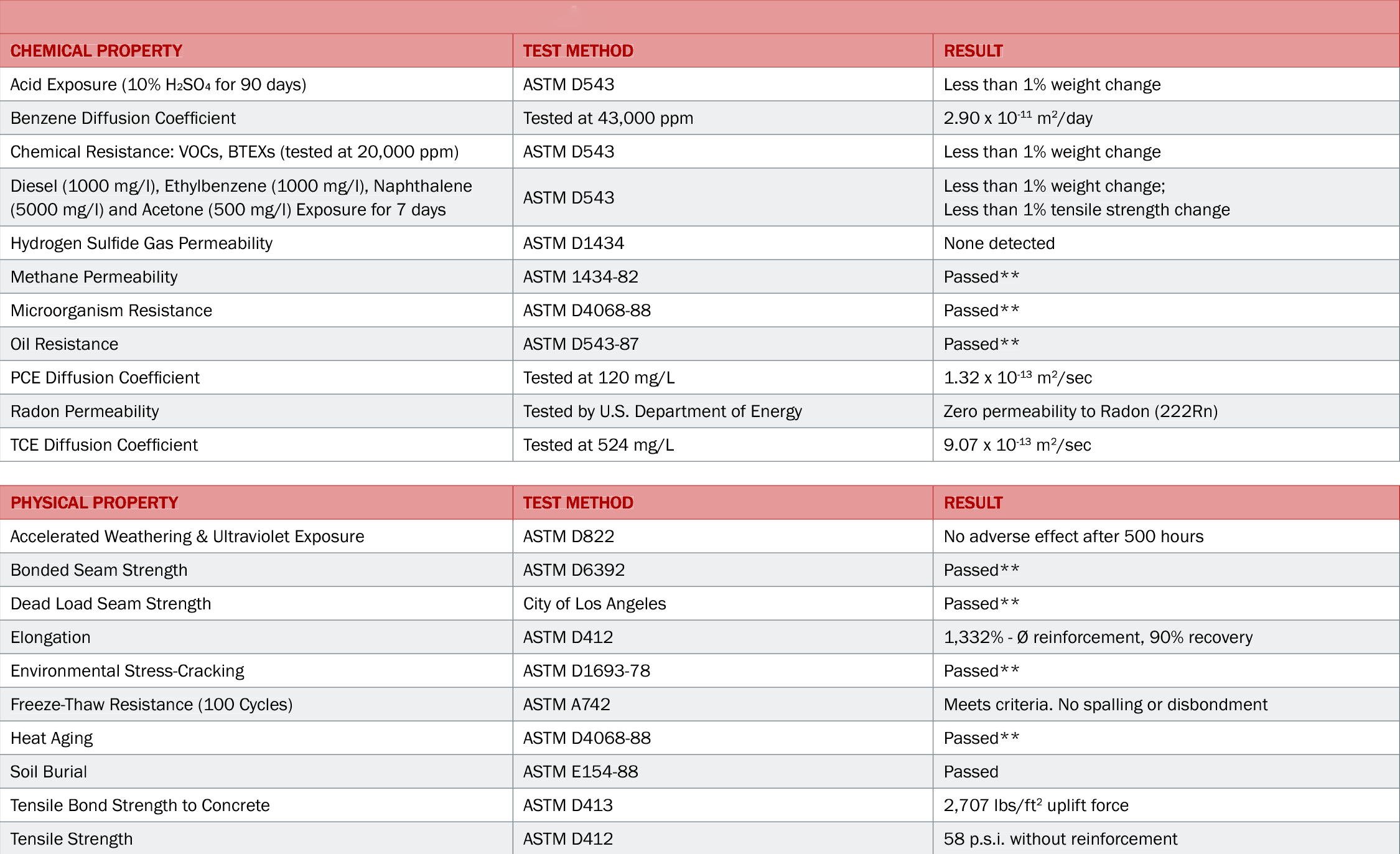

LIQUID BOOT CHEMICAL & PHYSICAL PROPERTIES*

LIQUID BOOT® — PLUS Gas Vapor Barrier System

System Description

The Liquid Boot® PLUS system is a combination of the traditional Liquid Boot® spray-applied membrane and VI-20™, a 20-mil, high performance polyethylene-EVOH copolymer membrane.

The system, paired with the GeoVent™ Gas Venting System, is designed to provide excellent resistance to contaminants.

The Liquid Boot® membrane is spray-applied to a uniform substrate, provided by the VI-20™ geomembrane, bonding together to create a highly resistant protection barrier.

Once the membrane is fully cured, UltraShield™ non-woven geotexile protection course is installed.

Typical Uses

Installed under slab and on below grade vertical walls as a gas vapor barrier to minimize

vapor and nuisance water (non-hydrostatic conditions) migration into buildings.

Ideal for applications with chlorinated solvents, BTEX and other PAHs.

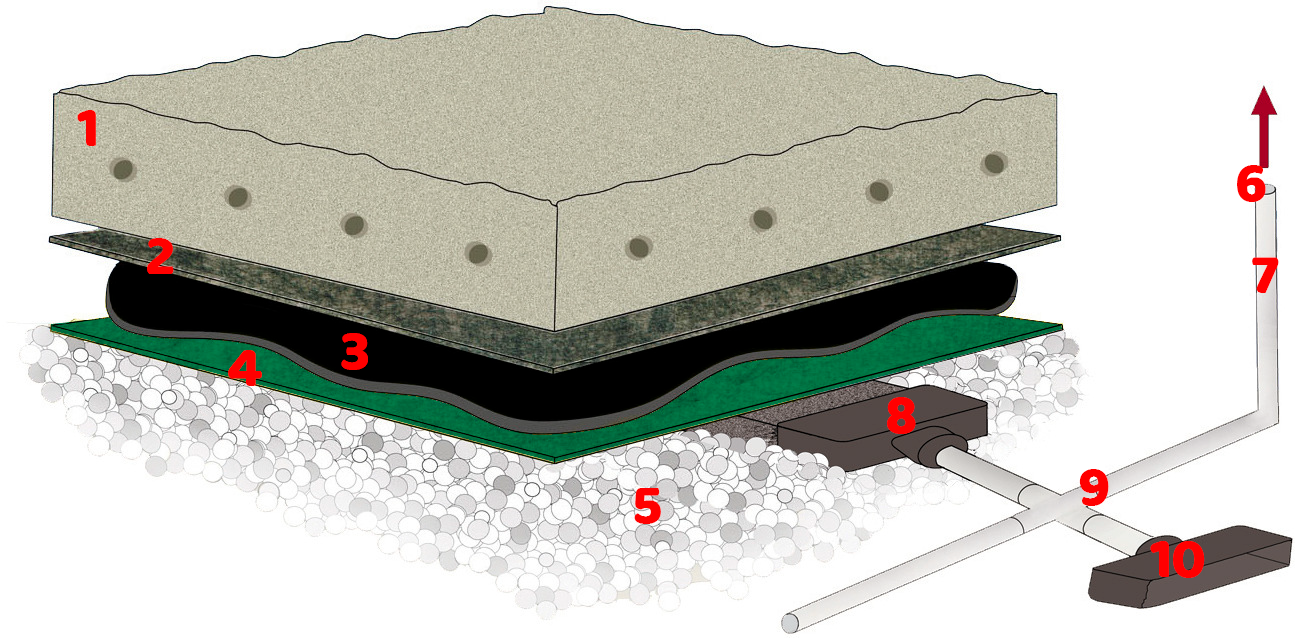

Structural Slab

UltraShield™ Protection Layer

LIQUID BOOT®

VI-20™ Geomembrane

GeoVent™ System

Subgrade

Benefits

Combines the advantages of a spray-applied membrane with the performance of a technically advanced geomembrane.

60 mil Liquid Boot® plus 20 mil VI-20™ provides excellent resistance to punctures and tears.

VI-20™ EVOH barrier technology provides superior protection against diffusion of chemicals

when compared to typical HDPE geomembranes.

VI-20™ Superior Performance Geomembrane With Evoh Technology

The Liquid Boot® PLUS system is a combination of the traditional Liquid Boot® spray-applied membrane and VI-20™, a 20-mil, high performance polyethylene-EVOH copolymer membrane.

The system, paired with the GeoVent™ Gas Venting System, is designed to provide excellent resistance to contaminants. The Liquid Boot® membrane is spray-applied to a uniform substrate, provided by the VI-20™ geomembrane, bonding together to create a highly resistant protection barrier. Once the membrane is fully cured, UltraShield™ non-woven geotexile protection course is installed.

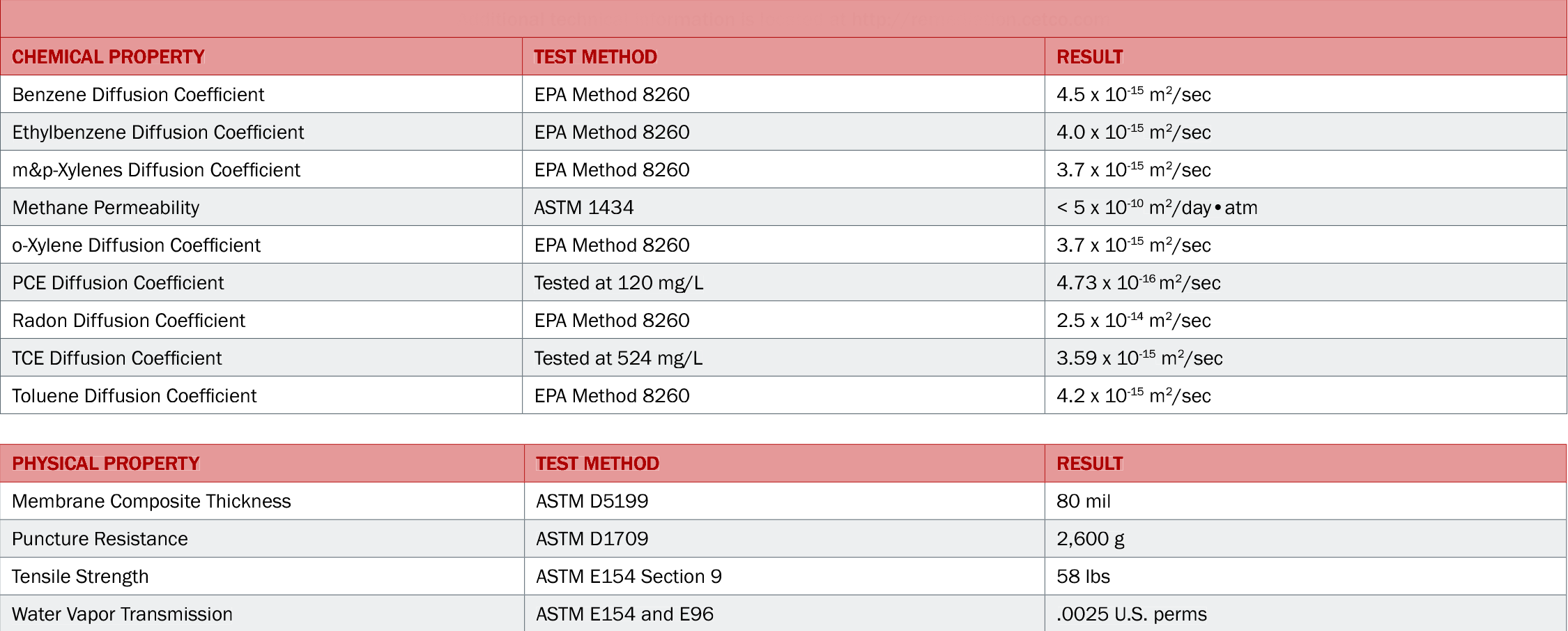

LIQUID BOOT with VI-20™ CHEMICAL & PHYSICAL PROPERTIES*

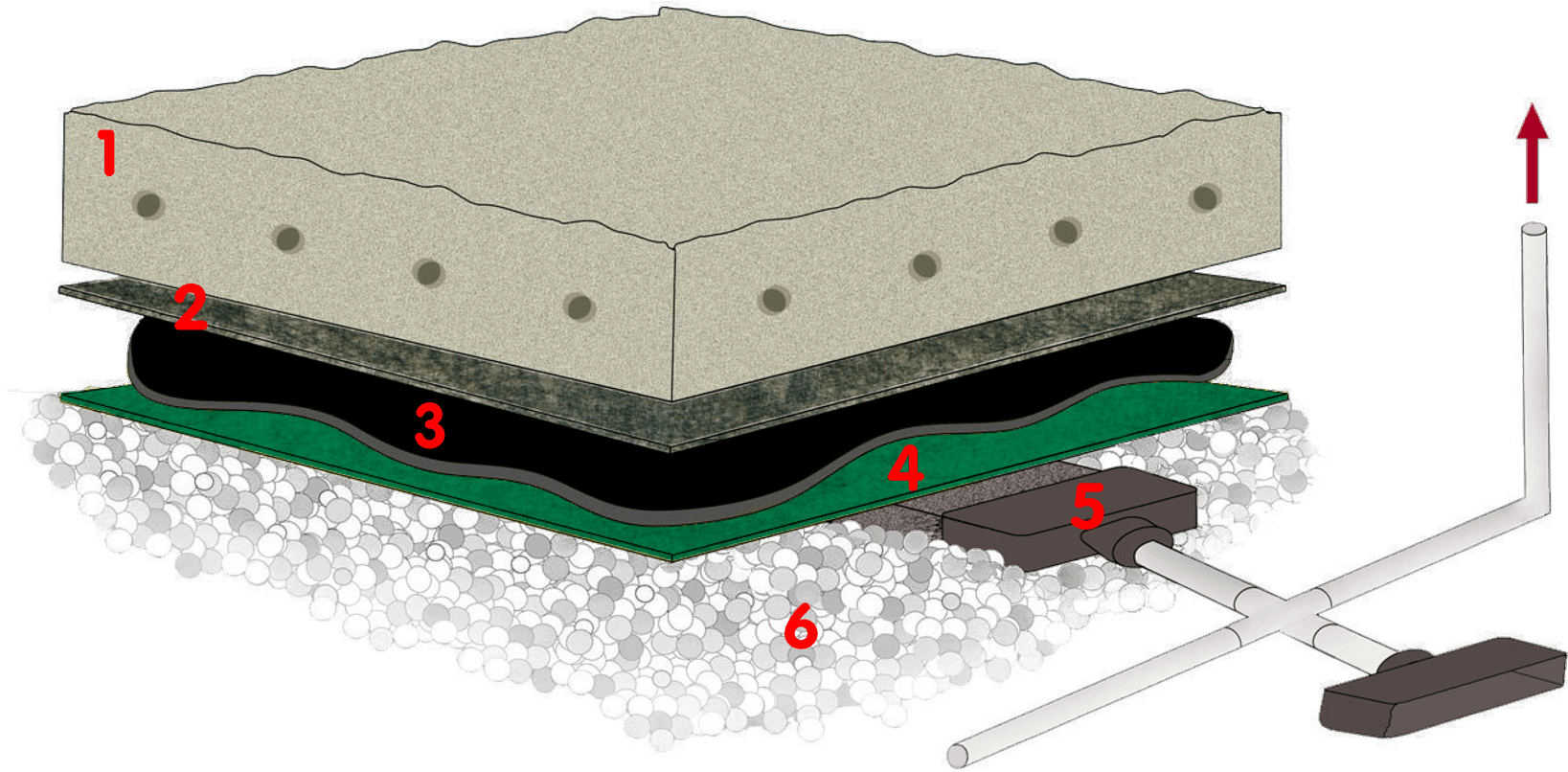

GeoVent™ — Gas Venting System

System Description

GeoVent™ is a low profile pressure relief, trenchless collection and venting system designed to improve venting efficiency and reduce installation costs. GeoVent™ has several advantages over trenched installations and can be used as an “active” or “passive” venting system depending on the specific project.

Used in conjunction with Liquid Boot® or CoreFlex™ gas vapor barrier systems, GeoVent™ can alleviate the accumulation of gas vapors under the slab.

Typical Use

Structural Slab

Protection

Membrane

Base Layer

Subgrade

Gas Venting

Vent Riser

GeoVent™

Header Pipe

End Outlet

Benefits

Greater opening area per linear foot of pipe and integral filter fabric allowing for higher ventilation efficiency.

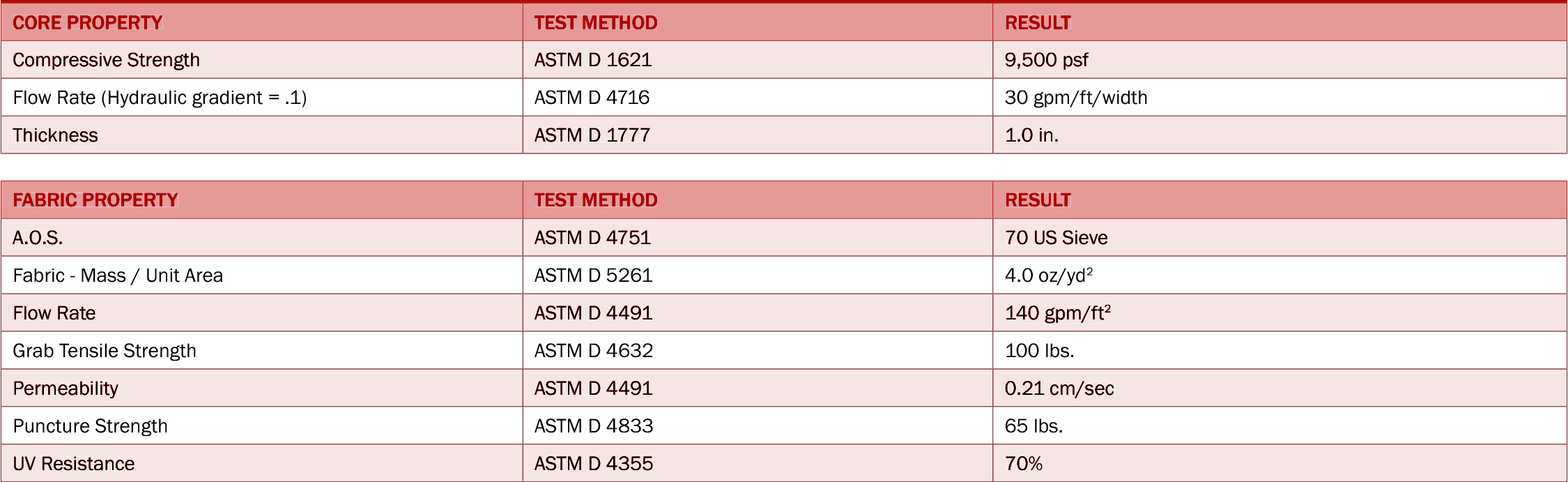

GeoVent™ CHEMICAL & PHYSICAL PROPERTIES*

Get A Quote Today!

Trident Environmental Group© 1994 – 2021 All Rights Reserved.